People & Programs

Melyssa Fratkin

Related Articles

Platform for Discovery

Modeling safe, efficient offshore extraction with Frontera

Do you use natural gas to heat your home or cook your dinner? Do you know how it got there? About one-half of the homes in the U.S. use natural gas for heating, cooking, and drying clothes. Texas homes and businesses used about 15 percent of the natural gas consumed in the U.S. in 2018 — more than double the usage of any other state. But getting the natural gas to our homes and businesses can be a challenge. It starts underground — or in many cases, underwater, buried deep in the seafloor.

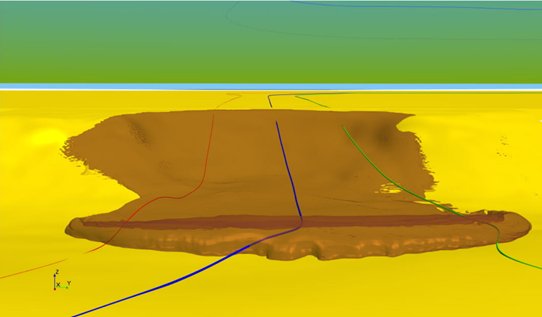

When energy companies deploy offshore platforms to retrieve natural gas, they need to understand the seafloor where the pipe will be inserted.

Researchers from TechnipFMC Genesis, a member of TACC’s STAR industrial affiliates program, have been using Frontera to model underwater landslides that may happen around pipe insertion points, using the system to produce scalable, high-resolution simulations of both the 50 centimeter pipeline and a 250,000-square-meter area around the insertion site. Landslides, which can be caused by shifting sediment, hurricanes, earthquakes, or other natural events, can damage or rupture the pipeline. It’s important to understand the impact that these events might have, and how the pipe will hold up against the stress.

Once the natural gas is brought to the surface, it has to be liquefied and cooled to -162 degrees Celsius (-260o F) for transport. The liquefied natural gas can then be shipped to places that natural gas pipelines don’t reach, and can be used as a transportation fuel.

Until recently, natural gas had to be transported to an on-shore facility to be liquefied. About 10 years ago, Shell Oil Company — also a member of the STAR industrial affiliates program — began searching for a way to liquefy natural gas offshore. Shell has now deployed the world’s largest floating structure, the Prelude Floating Liquid Natural Gas facility, which can process more than 3.5 million tons of liquified natural gas per year.

Sitting about 125 miles off the coast of Australia, Prelude is over 500 yards long — longer than four soccer fields placed end-to-end. The structure can pivot around a large turret, minimizing the impact of wind, current, and large ocean waves. It uses cold water from the depths of the ocean to support the liquefaction process. Shell and TechnipFMC have used the computational power of Frontera to model these computational fluid dynamics problems: the wave impacts, the water intake pipes, and the rotation of the structure.

“Before, we couldn’t see the detail on the water intake risers; we had to model them as a single cylinder. Moving from Stampede2 to Frontera gave us a great increase in performance,” said TechnipFMC Genesis researcher Lawrence Lai. “It lets us see the simulations at the micro- and macro-scale at the same time.”

“Fluid dynamics simulations have always been a cornerstone of the research done on TACC systems,” said Melyssa Fratkin, TACC’s Industrial Programs director. “Shell and TechnipFMC are two of our longest-standing industry partners, so it’s a pleasure to support this project and see their hard work solidified.”

The STAR program promotes the mutually beneficial exchange of ideas and information between industry and academia in advanced computing technologies, while fostering innovation and supporting economic development in the state of Texas and across the nation. For more information, visit: www.tacc.utexas.edu/partnerships/industry